HOW DOES IT WORK

No other system provides as many advantages

The principle of the system

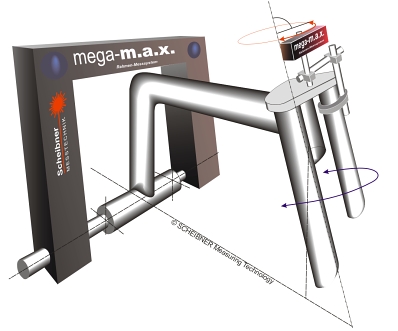

The mega-m.a.x. is a new optoelectronic system which is microprocessor controlled. The principal components are a large measuring bracket with two electronic measuring cameras, the sighting or ‘target’ bracket with two infrared illuminated targets and an integrated microprocessor. The controlling and measuring program includes the motorcycle manufacturers reference data. The program runs on a Laptop. The measuring cameras take the position of the targets at the front of the bike. Several measurements at different positions of the handlebar deliver the data for the microprocessor to calculate the exact steering head axis.

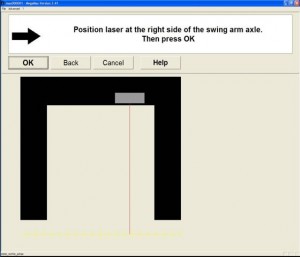

This means the mega-m.a.x.-measures the bike without removal of the front fork and most likely any other part other than to gain access for mounting, but the results are 100% unaffected by any possible distortion of the front fork. An adapted laser for minor jobs such as the measuring of the sub-frame and the swingarm, is included on the system. The display shows the ‘easy to understand’ instructions for the mounting of the gauge and the complete measuring procedure. The results from the measurement makes it easy to compare the results with the bike manufacturers specifications.

Mounting – Positioning

Innovative Technology

The Basic Steps Of The Measuring Procedure

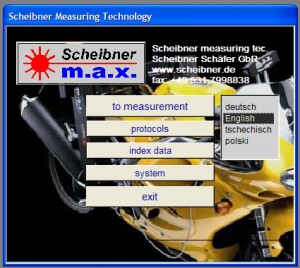

Software & Updates

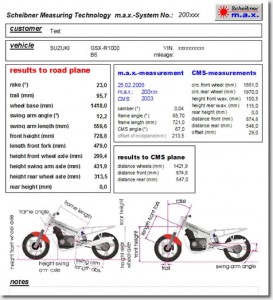

The M.a.x. – Measurement Report

If the Chassis is out of Spec

If the motorcycle needs to be straightened, we have the most accurate jig available – the “MOTO-JIG”. The Moto-Jig is manufactured by Globaljig, (one of the most experienced and respected companies in the business) and was designed to work in conjunction with the mega-M.A.X. System. Unlike other systems that require the motorcycle to be removed from the straightening jig to be remeasured, the design of the Moto-Jig and the mega-M.A.X. system allow us to verify the measurements while the motorcycle is still in the jig. This ensures accuracy and saves time – getting you back on the road sooner!

As always MPH has taken these two pieces of equipment and made them even better. We have designed and manufactured adapters and additional fixtures to work in conjunction with the latest advances in the manufacturers frame technology including Harley Davidson’s, Suzuki, Kawasaki, Honda, and Yamaha to name a few. The reason for the additional time and development cost incurred on MPH, at the end of the day it is to give you better service.

Due to the experience and expertise straightening motorcycle frames for the last 20 years, Nationwide, Geico, State Farm, and other Insurance Companies have used our services to repair and straighten frames. For further information check out our insurance repair. – more

CHASSIS MAXIMIZING SYSTEM SIMULATION

The computer software has a simulation feature built in that works in conjunction with the Chassis Maximizing System (CMS) that allows us to “virtually” test setup changes to the motorcycle BEFORE you hit the road. The software program computes changes in front and/or rear ride height, tire diameter differences, swing arm length changes due to sprocket size or swingarm extensions, etc. before we actually make the physical changes to bike directly. The CMS is a precision rail that works in conjunction with the mega-m.a.x. to acquire all the measurements needed to calculate numerous key factors to give us this numeric motorcycle. This also allows us to see the effects of simulated modifications to the rake, trail, and swingarm slope or any other figures in the table, on screen in advance.

The additional CMS (Chassis Maximizing System) will provide all you need for the fine-tuning of the chassis. The system has a simulation feature that allows you to fine tune the geometry of your bike right on the computer screen.

Optimum chassis setup for any customer with sporting ambitions, or just wanting to change tire manufacturer and restore their handling characteristics. For example, we can see what effect changing tire brands or tire sizes will have on rake, trail, swing-arm slope, or any of the other values due to tire diameter differences from one brand to another.

What it all boils down to is making motorcycle riding more fun and more comfortable, riding a little safer and more predictable. Whatever your needs may be – crash repair, a more comfortable ride, better handling – our revolutionary procedures help motorcycles perform the best they can. We solve problems that some riders don’t even know they have. Look at it this way, you don’t know better till you have ridden a better setup. You will be amazed with the results.